Background

In 2017 I worked with Nick Andrews and Heidi Noordijk at the North Willamette Research and Extension Center (NWREC) to help them develop a small wash and pack area to go with their Organic vegetable learning farm. The work was funded by a Clackamas Extension Innovation Grant. Part of the project was to design a few essential pieces of “furniture.”

I designed and built prototypes for three pieces and the spray table shown above is the first one I’m writing up here. You can find the packing table write up here and the harvest tote washer here.

The intention for the packing shed goes beyond just creating a functional space for packing vegetables out of the trial field, it’s also meant to be a testing ground for equipment, and a demonstration and teaching space for new and continuing farmers.

Basic Design

The initial request for this piece of furniture was something where vegetables can be sprayed down, cleaned and sorted. I based the design loosely on tables that I’ve built and used on several farms. Those tables were primarily made from wood, which is relatively inexpensive and easy to work with. It is unclear if it will be acceptable under the FSMA rules, thus the preference for this table was stainless steel. Stainless steel is a material that is definitely acceptable under any food safety rules. I also tried to incorporate adjustable height. Ergonomics is important and frequently farms have users of widely varying heights. I wanted the table to be quickly and easily adjusted to any users ideal working height. The table rolls so that it can be easily moved on a concrete slab allowing the work space to be quickly reconfigured and the floor beneath the table to be cleaned.

Tables I’ve designed and used extensively in the past have been 4’ wide which is roughly an arm span, allowing the user to reach both ends of the table without much movement. Usually I build shelves on the ends that allow the largest harvest totes used by the farm to sit flush with the table top, making it easy to move dirty product onto the table, and clean product off the other end. This table does not have the incorporated shelves (see Potential Future Improvements section for more on that).

I like to incorporate both a hanging hand operated sprayer and a hands-free, adjustable sprayer onto tables. The hands-free option allows the user to move product across the table with both hands while still spraying. With a hands-free sprayer, hands, or hand-held brushes, can be used to help rub soil and other debris off of the produce in addition to the spray without having to constantly pick up and put down the sprayer.

The hanging, hand operated sprayer is always conveniently located and never is in danger of touching the ground where it is easily contaminated. It is useful for spraying all corners of the table if the user prefers to dump a large pile of produce, or for cleaning the table after washing the produce.

For years I used mesh tables that just dumped spray water and mud at my feet and left me standing in a mud puddle. For the past 5 years I’ve been using tables that direct the water away from my feet. This table collects the water and pipes it away from the user. Because the table is mobile the pipe is not connected to a drain, but it can be positioned over a floor drain or a settling tub to help capture soil and debris before it goes down the drain.

One additional feature I find useful is a back splash. This prevents product (and water) from falling off the back of the table. I design tables for single users so they are one sided. I’ve found it difficult for more than one person to use a table at a time collaboratively so I design tables to work well for one user at a time and encourage farms to have more than one table if they need multiple users.

Because a sink is used in this design this table has the additional feature of a basin that can be filled with water for pre-soaking vegetables. I included two options of grates that can cover the sink basin so that the sink can be used solely as a spray table, in which case the basin of the sink just functions to catch the water and mud coming off of the vegetables and to funnel them into the drain pipe which comes out the side, or back of the table.

Construction Details

In researching the least expensive way to get a functional stainless surface that was appropriate I settled on using a single basin sink, double drain board restaurant sink. Because these sinks are mass produced they are relatively inexpensive and the dimensions are similar to the tables I’ve built in the past. The price of the sink isn’t much more than the actual price of the stainless steel so it’s definitely much cheaper than custom building a stainless table. There is also good availability of used restaurant sinks, although finding exactly the size you want might not always be possible.

For the sprayer I purchased a matching restaurant faucet and pre-rinse sprayer and attached a spray attachment with a quick on off trickle feature for the faucet. Pre-rinse sprayers are designed to hang above the sink and use a spring to keep them up out of the way, but easily in reach. The spray head for the faucet is a common retrofit for kitchen sinks. The quick on-off trickle feature is to save water, but it would be better if it shut off the water entirely (see photo in the previous section).

For the base of the sink I replaced the legs with a rolling adjustable height work cart. Like sinks, these are common enough that there are inexpensive versions available online. They are commonly used by mechanics for lifting heavy parts to a good working height, like engine blocks. The lift mechanism is operated with a simple foot pedal and it is lowered with a hand lever. Operation is quick and easy, and it will adjust to any height within a range.

I attached the sink to the cart with a wooden frame. That frame leaves just enough space for a drain pipe to extend out from the side, and the pipe could easily be extended to the rear, or redirected by attaching a drainage hose.

Water is supplied to the table by screwing in standard ¾” garden hose to the cold side. The hot water valve needs to be left closed, but can be opened to drain water from the system to keep it from freezing and breaking the faucet in cold weather.

| Part | Description | Source | Price |

| Sink | Regency 54” 16 gauge stainless steel one compartment commercial sink with 2 drainboards – 18x18x14” bowl | webstaurantstore.com | $345 + $146 shipping |

| Pre-rinse Sprayer with Faucet | 1.42 GPM wall mounted pre-rinse assembly with 8” centers and 12” add on faucet | webstaurantstore.com | $170 |

| Faucet Adapter | Necessary parts for mounting the faucet to the sink | webstaurantstore.com | $15 |

| Sink drain rack | Over the sink multipurpose stainless steel roll-up dish pot drying rack, 20.3” | Amazon.com | $29 |

| Sink drain kit | Drain tail piece plus 90 degree angled waste pipe. | Hardware store | $11 |

| Faucet spray nozzle | To replace aerator | Hardware store | $17 |

| Lift cart | Goplus Hydraulic Scissor Lift Table – 500lb Capacity | Amazon.com | $176 |

| 2×4 | (2) 17 5/8” rails

(2) 21” rails (2) 5” legs |

Lumber yard | $4 |

| 1×4 | (2) 17 5/8” side plates

(1) XXX” support for pre-rinse sprayer (1) 5” clamping piece |

Lumber yard | $4 |

| Angle brackets | Four 1×1/2” corner brackets to hold the frame down | Hardware store | $3 |

| Screws | Assortment of 1 ½ “ to 2 ½” deck screws to hold it all together | Hardware store | $5 |

| Pipe to hose adapter | ½” FPT to ¾” FHT adapter | Hardware store | $6.50 |

| Approximate parts TOTAL | $931.50 |

Assembly Instructions and Required Tools

Assembly of the sink and its plumbing is fairly straight forward. The faucet, pre-rinse sprayer assembly and faucet adapter all screw together using generous wraps of Teflon tape on the threads. Make sure to slide the hook onto the riser pipe for hanging the pre-rinse sprayer when the sprayer is not in use. The hose thread to pipe thread adapter gets screwed onto one of the faucet inlets on the back side of the sink using Teflon tape. I hooked it up to the “cold” side, but it doesn’t matter which you use. For screwing these parts together I mostly tightened by hand, but it was helpful to have a pipe wrench and a pair of channel lock pliers to snug everything down. The faucet surfaces are chromed so use a thick rag, copper jaws or something similar to protect the finish.

The aerator on the faucet is unscrewed and replaced with the spray nozzle (without Teflon tape – there is a washer that creates the seal). The pliers make this job easy. The threads only need to be snugged against the washer.

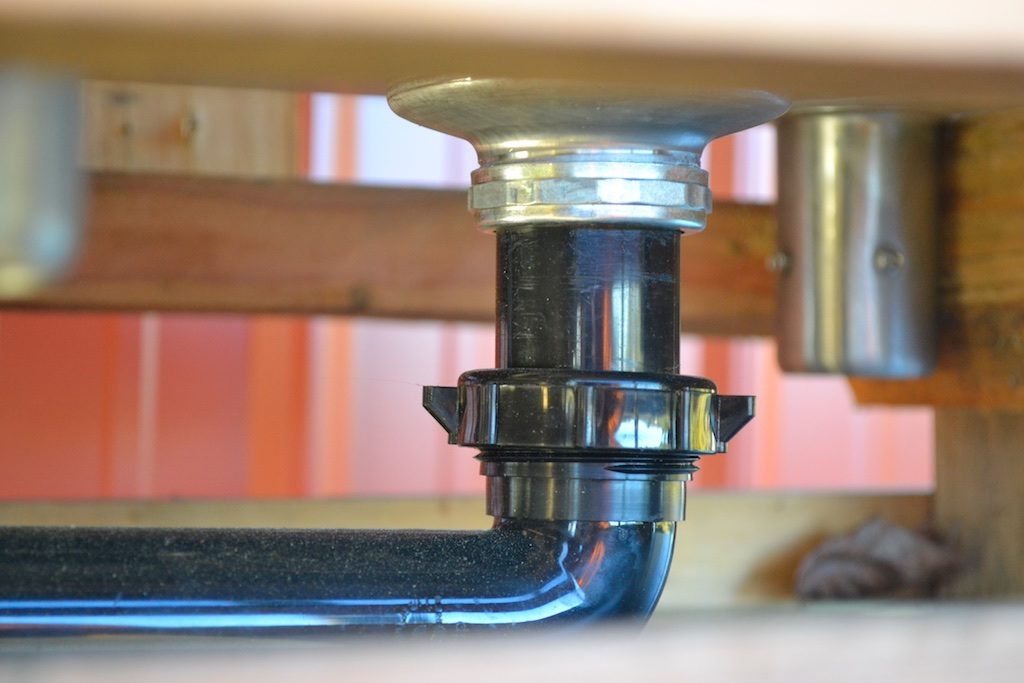

For the drain, screw in the drain cup using the rubber washer on the bottom side to make a seal with the sink bowl. Trim the tail piece so that there is just enough room to fit the waste pipe to it. Pretty much any hand saw can be used for trimming the plastic plumbing pieces.

To create a platform for the sink to sit on I used some scrap lumber. I’ve put suggested sizes in the parts list but you’ll need to measure your particular sink and cart to make sure the measurements work for your parts. I used a basic skill saw and drill driver to assemble these parts (see the photos above for good views of the platform).

I sized my platform so that it fit around the leg brackets snuggly on the outside. The sink is not actually attached to this wooden platform, other than a friction fit and gravity holding it in place. Using screws at the outsides corners, and predrilling holes for the screws to prevent splitting the wood, provides enough bracing to keep it all from wobbling since the legs are very short. The 1x plates on the front and back keep the platform from sliding off and I used the metal angle brackets to keep the wooden platform from lifting off of the cart.

I attached a long scrap of 1×4 to the back of the wooden platform that extended up above the sink in the back. A second short scrap of 1×4 with one end cut at a 45 degree angle to shed water is screwed to the long 1×4 and clamps it to the top edge of the stainless steel backsplash. Near the top of the 1×4 I drilled a hole with a spade bit to allow the support for the pre-rinse sprayer riser pipe to slide through. I screwed the bracket for the support to the 1×4 and fixed the support in place.

Potential Future Improvements

Incorporated shelves for the ends could be built as separate low stands next to the table, or in a future design update it might be good to use two lift carts tied together on either end of the table that would function as the low shelves. The hydraulics on the two carts could be coupled so that they lift simultaneously, allowing the shelves to maintain their relationship to the table top. This would also help to stabilize the entire work surface as it would move the cart wheels out to the edges.

It would be better if the casters on the cart had higher quality locking mechanisms. The ones that came with this very inexpensive cart are difficult to lock and are only single locking, meaning they still allow slight wobbling when locked.

The one feature of the sink itself that I don’t like is that the sides have a rolled edge that sticks up. This works well for a drain board that is designed to keep water going to the sink but in this application it would be nice if it were flush with the drain board to allow product to be slid off the end and into a clean bin sitting next to the table. This is a modification that could be made by a sheet metal worker. It would likely require cutting off the existing rolled side and then re-welding it beneath the drain board with gussets to maintain the structural integrity.

One of the biggest problems I see immediately with this design is that the limited diameter of the plumbing on the standard faucet and pre-rinse sprayer reduces the flow. This potentially saves water, but it also increases the time to wash very muddy roots or to fill the sink basin. There’s no easy way around this, other than building custom plumbing to replace these parts. On my own wash table I use a length of 3/4″ garden hose with a garden sprayer hanging over the table and an adjustable shower arm with a high pressure head (from a bathroom shower) instead of the more standard sink parts. This looks a bit funky, and takes some fiddling with parts to make it fit, but it does allow more water to flow when needed.

The current design in general is not super stable, due partly to the relatively narrow stance of the wheels on the cart in relation to the overall width of the sink. A second potential stability problem is that the sink is not actually positively attached to the wooden stand, and relies on a tight fit with the wooden stand and gravity to keep it in place. In most situations this should be fine but if the cart tips over due to uneven loading on the edges, or leaning too much against it the sink might separate from the stand and break the waste pipe. The single locking casters on the cart also don’t help the stability.

There are a number of ways the stability could be improved. As mentioned above adding a second cart would move the wheels out to the edges which would be a big improvement. The existing wheels could also be removed from the cart, or carts and replaced with an extra frame of either metal or wood that would extend the footprint. Higher quality double locking casters could keep the mobility high. Simply using fixed wheels on one end and feet on the other would improve stability with less expense, and would require that the cart be tipped up on the wheeled end to move, which would probably not be too difficult, especially for occasional moving.

On this version of the table the standard handle that comes with the lift cart is long enough that it prevents the table from fully descending. The handle is easily partially removed to allow the cart to be as short as possible, but without extra effort it cannot be completely removed as it incorporates the release lever that lowers the work platform. The handle could also be easily shortened by chopping it off a few inches and drilling new holes for the attaching pins.